Rotation's billet wheel designs are cut by CNC from 1 piece of solid aircraft-grade aluminum. The manufacturing process is quite extensive to create a finished wheel ready to install on your motorcycle. Below we will show some of the steps to make a custom billet motorcycle wheel.

Here is a picture of a solid wheel blank before going into production.

Next the blank is loaded on to the CNC machine to cut the design of the wheel. Here is a contrast wheel before receiving it's 2nd round of cutting.

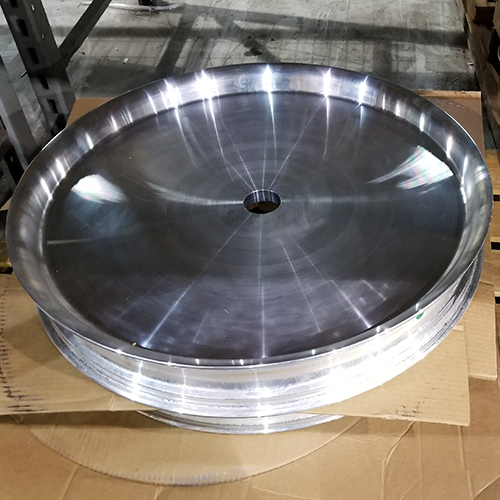

Here is a picture of a wheel after being cut, that is headed to polishing before getting chrome!

After the wheel is finished being cut, it will be loaded on to racks to be rolled over to assembly to mate the newly cut billet hub into the wheel before shipment.